Dihedral (Shanghai) Science and Technology Co., Ltd

Dihedral (Shanghai) Science and Technology Co., Ltd

- Home

-

Products

-

- Semiconductor crystal

-

Single crystal substrate

-

Multifunctional single crystal substrate

- Barium titanate (BaTiO3)

- Strontium titanate (SrTiO3)

- Iron doped strontium titanate (Fe:SrTiO3)

- Neodymium doped strontium titanate (Nd:SrTiO3)

- Aluminium oxide (Al2O3)

- Potassium tantalum oxide (KTaO3)

- Lead magnesium niobate–lead titanate (PMN-PT)

- Magnesium oxide (MgO)

- Magnesium aluminate spinel (MgAl2O4)

- Lithium aluminate (LiAlO2)

- Lanthanu m aluminate (LaAlO3)

- Lanthanu m strontium aluminate (LaSrAlO4)

- (La,Sr)(Al,Ta)O3

- Neodymium gallate (NdGaO3)

- Terbium gallium garnet (TGG)

- Gadolinium gallium garnet (GGG)

- Sodium chloride (NaCl)

- Potassium bromide (KBr)

- Potassium chloride (KCl)

-

Multifunctional single crystal substrate

-

Functional crystal

- Optical window

- Scintillation crystal

-

Laser crystal

- Rare earth doped lithium yttrium fluoride (RE:LiYF4)

- Rare earth doped lithium lutetium fluoride (RE:LiLuF4)

- Ytterbium doped yttrium aluminium garnet (Yb:YAG)

- Neodymium doped yttrium aluminium garnet (Nd:YAG)

- Erbium doped yttrium aluminium garnet (Er:YAG)

- Holmium doped yttrium aluminium garnet (Ho:YAG)

- Nd,Yb,Er,Tm,Ho,Cr,Lu Infrared laser crystal

- N* crystal

- Metal single crystal

- Material testing analysis

- Material processing

- Scientific research equipment

-

-

Epitaxial Wafer/Films

-

Inorganic epitaxial wafer/film

- Gallium Oxide epitaxial wafer (Ga2O3)

- ε - Gallium Oxide (Ga2O3)

- Platinum/Titanium/Silicon Dioxide/Silicon epitacial wafer (Pt/Ti/SiO2/Si)

- Lithium niobate thin film epitaxial wafer

- Lithium tantalate thin film epitaxial wafer

- InGaAs epitaxial wafer

- Gallium Nitride(GaN) epitaxial wafer

- Epitaxial silicon wafer

- Yttrium Iron Garnet(YIG) epitaxial wafers

- Fullerenes&Fullerols

- ε-Gallium Oxide(Ga2O3)

- Indium Arsenide (InAs) epitaxial wafer

- InGaAs and other compound epitaxial wafers

- Periodic polarization of lithium niobate PPLN and lithium tantalate PPLT

-

Inorganic epitaxial wafer/film

- Functional Glass

- Fine Ceramics

-

2-D material

- 2-D crystal

-

Layered transition metal compound

- Iron chloride (FeCl2)

- Niobium sulfide (NbS3)

- Gallium telluride iodide (GaTeI)

- Indium selenide (InSe)

- Copper indium phosphide sulfide (CuInP2S6)

- Tungsten sulfide selenide (WSSe)

- Iron germanium telluride (Fe3GeTe2)

- Nickel iodide (NiI2)

- Iron phosphorus sulfide (FePS3)

- Manganese phosphorus selenide (MnPSe3)

- Manganese phosphorus sulfide (MnPS3)

- Interface thermal conductive materials

-

Epitaxial Wafer/Films

-

-

High-purity element

- Non-metallic

-

Metal

- Scandium (Sc)

- Titanium (Ti)

- Indium (In)

- Gallium (Ga)

- Bismuth (Bi)

- Tin (Sn)

- Zinc (Zn)

- Cadmium (Cd)

- Antimony (Sb)

- Copper (Cu)

- Nickel (Ni)

- Molybdenum (Mo)

- Aluminium (Al)

- Rhenium (Re)

- Hafnium (Hf)

- Vanadium (V)

- Chromium (Cr)

- Iron (Fe)

- Cobalt (Co)

- Zirconium (Zr)

- Niobium (Nb)

- Tungsten (W)

- Germanium (Ge)

- Iron(Fe)

-

Compound raw materials

-

Oxide

- Tungsten Trioxide (WO3)

- Hafnium Dioxide (HfO2)

- Ytterbium Oxide (Yb2O3)

- Erbium Oxide (Er2O3)

- Lanthanu m Oxide (La2O3)

- Cerium Dioxide (CeO2)

- Tin Dioxide (SnO2)

- Niobium Oxide (Nb2O3)

- Zirconium Dioxide (ZrO2)

- Zinc Oxide (ZnO)

- Copper Oxide (CuO)

- Magnetite (Fe3O4)

- Titanium Dioxide (TiO2)

- Samarium (III) oxide (Sm2O3)

- Silicon Dioxide (SiO2)

- Aluminum Oxide (Al2O3)

- Gallium Oxide Ga2O3(Powder)

- Sulfide

- Fluoride

- Nitride

- Carbide

-

Halide

- Gallium Chloride (GaCl3)

- Indium Chloride (InCl3)

- Aluminum Chloride (AlCl3)

- Bismuth Chloride (BiCl3)

- Cadmium Chloride (CdCl2)

- Chromium Chloride (CrCl2)

- Chromium Chloride Hydrate (CrCl2(H2O)n)

- Copper Chloride (CuCl)

- Copper Chloride II (CuCl2)

- Cesium Chloride (CsCl)

- Europium Chloride (EuCl3)

- Europium Chloride Hydrate (EuCl3.xH2O)

- Magnesium Chloride (MgCl2)

- Sodium Chloride (NaCl)

- Nickel Chloride (NiCl2)

- Indium Chloride (InCl3)

- Indium Nitrate Hydrate (In(NO3).xH2O)

- Rubidium Chloride (RbCl3)

- Antimony Chloride (SbCl3)

- Samarium Chloride (SmCl3)

- Samarium Chloride Hydrate (SmCl3.xH2O)

- Scandium Chloride (ScCl3)

- Tellurium Chloride (TeCl3)

- Tantalum Chloride (TaCl5)

- Tungsten Chloride (WCl6)

- Aluminum Bromide (AlBr3)

- Barium Bromide (BaBr2)

- Cobalt Bromide (CoBr2)

- Cadmium Bromide (CdBr2)

- Gallium Bromide (GaBr3)

- Gallium Bromide Hydrate (GaBr3.xH2O)

- Nickel Bromide (NiBr2)

- Potassium Bromide (KBr)

- Lead Bromide (PbBr2)

- Zirconium Bromide (ZrBr2)

- Bismuth Bromide (BiBr4)

- Bismuth Iodide (BiI3)

- Calcium Iodide (CaI2)

- Gadolinium Iodide (GdI2)

- Cobalt Iodide (CoI2)

- Cesium Iodide (CsI)

- Europium Iodide (EuI2)

- Lithium Iodide (LiI)

- Lithium Iodide Hydrate (LiI.xH2O)

- Gallium Iodide (GaI3)

- Gadolinium Iodide (GdI3)

- Indium Iodide (InI3)

- Potassium Iodide (KI)

- Lanthanu m Iodide (LaI3)

- Lutetium Iodide (LuI3)

- Magnesium Iodide (MgI2)

- Sodium Iodide (NaI)

-

Oxide

-

High-purity element

-

-

Sputtering Target

-

Metal target material

- Gold (Au(T))

- Silver (Ag(T))

- Platinum (Pt(T))

- Palladium (Pd(T))

- Ruthenium (Ru(T))

- Iridium (Ir(T))

- Aluminium (Al(T))

- Copper (Cu(T))

- Titanium (Ti(T))

- Nickel (Ni(T))

- Chromium (Cr(T))

- Cobalt (Co(T))

- Iron (Fe(T))

- Manganese (Mn(T))

- Zinc (Zn(T))

- Vanadium (V(T))

- Tungsten (W(T))

- Hafnium (Hf(T))

- Niobium (Nb(T))

- Molybdenum (Mo(T))

- Lanthanu m (La (T))

- Cerium (Ce (T))

- Praseodymium (Pr (T))

- Neodymium (Nd (T))

- Samarium (Sm (T))

- Europium (Eu (T))

- Gadolinium (Gd (T))

- Terbium (Tb (T))

- Dysprosium (Dy (T))

- Holmium (Ho (T))

- Erbium (Er (T))

- Thulium (Tm (T))

- Ytterbium (Yb (T))

- Lutetium (Lu (T))

- Alloy target material

- Semiconductor target material

-

Oxide target material

- Aluminum Oxide (Al2O3(T))

- Silicon Dioxide (SiO2(T))

- Titanium Dioxide (TiO2(T))

- Chromium Oxide (Cr2O3(T))

- Nickel Oxide (NiO(T))

- Copper Oxide (CuO(T))

- Zinc Oxide (ZnO(T))

- Zirconium Oxide (ZrO2(T))

- Indium Tin Oxide (ITO(T))

- Indium Zinc Oxide (IZO(T))

- Aluminum Doped Zinc Oxide (AZO(T))

- Cerium Oxide (CeO2(T))

- Tungsten Trioxide (WO3(T))

- Hafnium Oxide (HfO2(T))

- Indium Gallium Zinc Oxide (IGZO(T))

- Nitride target material

- Sulfide target material

-

Antimony tellurium selenium boron target material

- Magnesium Boride (MgB2(T))

- Lanthanu m Hexaboride (LaB6(T))

- Titanium Diboride (TiB2(T))

- Zinc Selenide (ZnSe(T))

- Zinc Antimonide (Zn4Sb3(T))

- Cadmium Selenide (CdSe(T))

- Indium Telluride (In2Te3(T))

- Tin Selenide (SnSe(T))

- Germanium Antimonide (GeSb(T))

- Antimony Selenide (Sb2Se3(T))

- Antimony Telluride (Sb2Te3(T))

- Bismuth Telluride (Bi2Te3(T))

-

Metal target material

-

Sputtering Target

-

- Services

- Media

- Partner

- Contact Us

- About

- Home

- Products

- Epitaxial Wafer/Films

- Inorganic epitaxial wafer/film

- Semiconductor crystal

-

Functional crystal

- Optical window

- Scintillation crystal

-

Laser crystal

- Rare earth doped lithium yttrium fluoride (RE:LiYF4)

- Rare earth doped lithium lutetium fluoride (RE:LiLuF4)

- Ytterbium doped yttrium aluminium garnet (Yb:YAG)

- Neodymium doped yttrium aluminium garnet (Nd:YAG)

- Erbium doped yttrium aluminium garnet (Er:YAG)

- Holmium doped yttrium aluminium garnet (Ho:YAG)

- Nd,Yb,Er,Tm,Ho,Cr,Lu Infrared laser crystal

- N* crystal

- Metal single crystal

-

2-D material

- 2-D crystal

-

Layered transition metal compound

- Iron chloride (FeCl2)

- Niobium sulfide (NbS3)

- Gallium telluride iodide (GaTeI)

- Indium selenide (InSe)

- Copper indium phosphide sulfide (CuInP2S6)

- Tungsten sulfide selenide (WSSe)

- Iron germanium telluride (Fe3GeTe2)

- Nickel iodide (NiI2)

- Iron phosphorus sulfide (FePS3)

- Manganese phosphorus selenide (MnPSe3)

- Manganese phosphorus sulfide (MnPS3)

-

High-purity element

- Non-metallic

-

Metal

- Scandium (Sc)

- Titanium (Ti)

- Indium (In)

- Gallium (Ga)

- Bismuth (Bi)

- Tin (Sn)

- Zinc (Zn)

- Cadmium (Cd)

- Antimony (Sb)

- Copper (Cu)

- Nickel (Ni)

- Molybdenum (Mo)

- Aluminium (Al)

- Rhenium (Re)

- Hafnium (Hf)

- Vanadium (V)

- Chromium (Cr)

- Iron (Fe)

- Cobalt (Co)

- Zirconium (Zr)

- Niobium (Nb)

- Tungsten (W)

- Germanium (Ge)

- Iron(Fe)

-

Single crystal substrate

-

Multifunctional single crystal substrate

- Barium titanate (BaTiO3)

- Strontium titanate (SrTiO3)

- Iron doped strontium titanate (Fe:SrTiO3)

- Neodymium doped strontium titanate (Nd:SrTiO3)

- Aluminium oxide (Al2O3)

- Potassium tantalum oxide (KTaO3)

- Lead magnesium niobate–lead titanate (PMN-PT)

- Magnesium oxide (MgO)

- Magnesium aluminate spinel (MgAl2O4)

- Lithium aluminate (LiAlO2)

- Lanthanu m aluminate (LaAlO3)

- Lanthanu m strontium aluminate (LaSrAlO4)

- (La,Sr)(Al,Ta)O3

- Neodymium gallate (NdGaO3)

- Terbium gallium garnet (TGG)

- Gadolinium gallium garnet (GGG)

- Sodium chloride (NaCl)

- Potassium bromide (KBr)

- Potassium chloride (KCl)

-

Multifunctional single crystal substrate

-

Sputtering Target

-

Metal target material

- Gold (Au(T))

- Silver (Ag(T))

- Platinum (Pt(T))

- Palladium (Pd(T))

- Ruthenium (Ru(T))

- Iridium (Ir(T))

- Aluminium (Al(T))

- Copper (Cu(T))

- Titanium (Ti(T))

- Nickel (Ni(T))

- Chromium (Cr(T))

- Cobalt (Co(T))

- Iron (Fe(T))

- Manganese (Mn(T))

- Zinc (Zn(T))

- Vanadium (V(T))

- Tungsten (W(T))

- Hafnium (Hf(T))

- Niobium (Nb(T))

- Molybdenum (Mo(T))

- Lanthanu m (La (T))

- Cerium (Ce (T))

- Praseodymium (Pr (T))

- Neodymium (Nd (T))

- Samarium (Sm (T))

- Europium (Eu (T))

- Gadolinium (Gd (T))

- Terbium (Tb (T))

- Dysprosium (Dy (T))

- Holmium (Ho (T))

- Erbium (Er (T))

- Thulium (Tm (T))

- Ytterbium (Yb (T))

- Lutetium (Lu (T))

- Alloy target material

- Semiconductor target material

-

Oxide target material

- Aluminum Oxide (Al2O3(T))

- Silicon Dioxide (SiO2(T))

- Titanium Dioxide (TiO2(T))

- Chromium Oxide (Cr2O3(T))

- Nickel Oxide (NiO(T))

- Copper Oxide (CuO(T))

- Zinc Oxide (ZnO(T))

- Zirconium Oxide (ZrO2(T))

- Indium Tin Oxide (ITO(T))

- Indium Zinc Oxide (IZO(T))

- Aluminum Doped Zinc Oxide (AZO(T))

- Cerium Oxide (CeO2(T))

- Tungsten Trioxide (WO3(T))

- Hafnium Oxide (HfO2(T))

- Indium Gallium Zinc Oxide (IGZO(T))

- Nitride target material

- Sulfide target material

-

Antimony tellurium selenium boron target material

- Magnesium Boride (MgB2(T))

- Lanthanu m Hexaboride (LaB6(T))

- Titanium Diboride (TiB2(T))

- Zinc Selenide (ZnSe(T))

- Zinc Antimonide (Zn4Sb3(T))

- Cadmium Selenide (CdSe(T))

- Indium Telluride (In2Te3(T))

- Tin Selenide (SnSe(T))

- Germanium Antimonide (GeSb(T))

- Antimony Selenide (Sb2Se3(T))

- Antimony Telluride (Sb2Te3(T))

- Bismuth Telluride (Bi2Te3(T))

-

Metal target material

- Interface thermal conductive materials

-

Compound raw materials

-

Oxide

- Tungsten Trioxide (WO3)

- Hafnium Dioxide (HfO2)

- Ytterbium Oxide (Yb2O3)

- Erbium Oxide (Er2O3)

- Lanthanu m Oxide (La2O3)

- Cerium Dioxide (CeO2)

- Tin Dioxide (SnO2)

- Niobium Oxide (Nb2O3)

- Zirconium Dioxide (ZrO2)

- Zinc Oxide (ZnO)

- Copper Oxide (CuO)

- Magnetite (Fe3O4)

- Titanium Dioxide (TiO2)

- Samarium (III) oxide (Sm2O3)

- Silicon Dioxide (SiO2)

- Aluminum Oxide (Al2O3)

- Gallium Oxide Ga2O3(Powder)

- Sulfide

- Fluoride

- Nitride

- Carbide

-

Halide

- Gallium Chloride (GaCl3)

- Indium Chloride (InCl3)

- Aluminum Chloride (AlCl3)

- Bismuth Chloride (BiCl3)

- Cadmium Chloride (CdCl2)

- Chromium Chloride (CrCl2)

- Chromium Chloride Hydrate (CrCl2(H2O)n)

- Copper Chloride (CuCl)

- Copper Chloride II (CuCl2)

- Cesium Chloride (CsCl)

- Europium Chloride (EuCl3)

- Europium Chloride Hydrate (EuCl3.xH2O)

- Magnesium Chloride (MgCl2)

- Sodium Chloride (NaCl)

- Nickel Chloride (NiCl2)

- Indium Chloride (InCl3)

- Indium Nitrate Hydrate (In(NO3).xH2O)

- Rubidium Chloride (RbCl3)

- Antimony Chloride (SbCl3)

- Samarium Chloride (SmCl3)

- Samarium Chloride Hydrate (SmCl3.xH2O)

- Scandium Chloride (ScCl3)

- Tellurium Chloride (TeCl3)

- Tantalum Chloride (TaCl5)

- Tungsten Chloride (WCl6)

- Aluminum Bromide (AlBr3)

- Barium Bromide (BaBr2)

- Cobalt Bromide (CoBr2)

- Cadmium Bromide (CdBr2)

- Gallium Bromide (GaBr3)

- Gallium Bromide Hydrate (GaBr3.xH2O)

- Nickel Bromide (NiBr2)

- Potassium Bromide (KBr)

- Lead Bromide (PbBr2)

- Zirconium Bromide (ZrBr2)

- Bismuth Bromide (BiBr4)

- Bismuth Iodide (BiI3)

- Calcium Iodide (CaI2)

- Gadolinium Iodide (GdI2)

- Cobalt Iodide (CoI2)

- Cesium Iodide (CsI)

- Europium Iodide (EuI2)

- Lithium Iodide (LiI)

- Lithium Iodide Hydrate (LiI.xH2O)

- Gallium Iodide (GaI3)

- Gadolinium Iodide (GdI3)

- Indium Iodide (InI3)

- Potassium Iodide (KI)

- Lanthanu m Iodide (LaI3)

- Lutetium Iodide (LuI3)

- Magnesium Iodide (MgI2)

- Sodium Iodide (NaI)

-

Oxide

-

Epitaxial Wafer/Films

-

Inorganic epitaxial wafer/film

- Gallium Oxide epitaxial wafer (Ga2O3)

- ε - Gallium Oxide (Ga2O3)

- Platinum/Titanium/Silicon Dioxide/Silicon epitacial wafer (Pt/Ti/SiO2/Si)

- Lithium niobate thin film epitaxial wafer

- Lithium tantalate thin film epitaxial wafer

- InGaAs epitaxial wafer

- Gallium Nitride(GaN) epitaxial wafer

- Epitaxial silicon wafer

- Yttrium Iron Garnet(YIG) epitaxial wafers

- Fullerenes&Fullerols

- ε-Gallium Oxide(Ga2O3)

- Indium Arsenide (InAs) epitaxial wafer

- InGaAs and other compound epitaxial wafers

- Periodic polarization of lithium niobate PPLN and lithium tantalate PPLT

-

Inorganic epitaxial wafer/film

- Material testing analysis

- Scientific research equipment

- Material processing

- Functional Glass

- Fine Ceramics

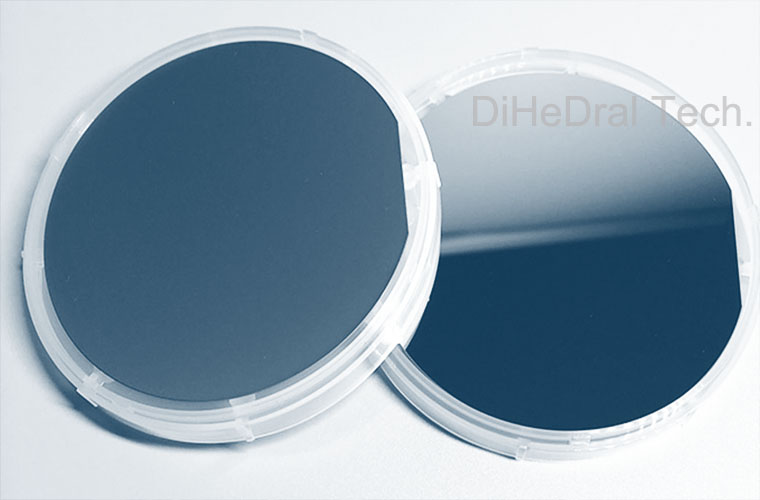

Inorganic epitaxial wafer/film

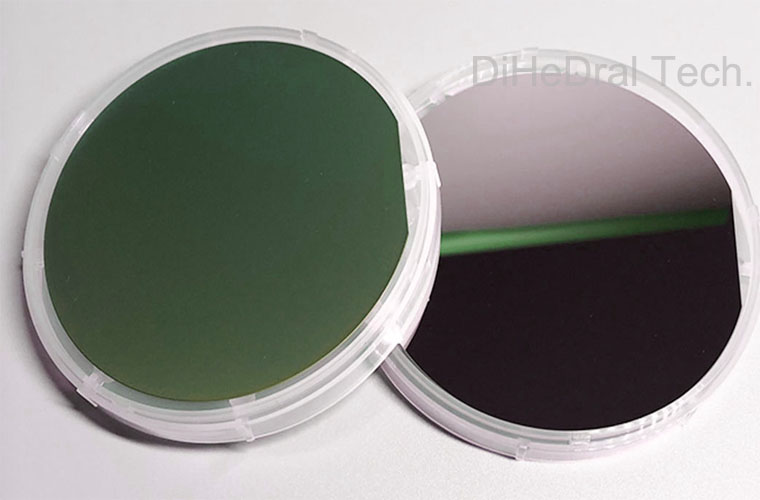

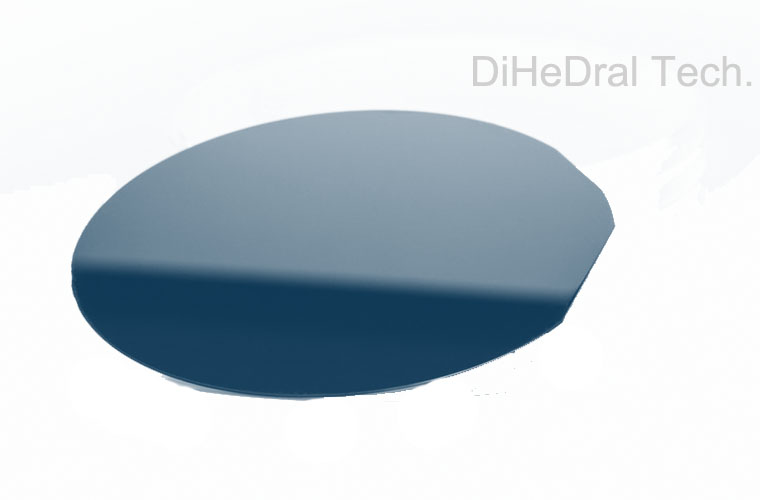

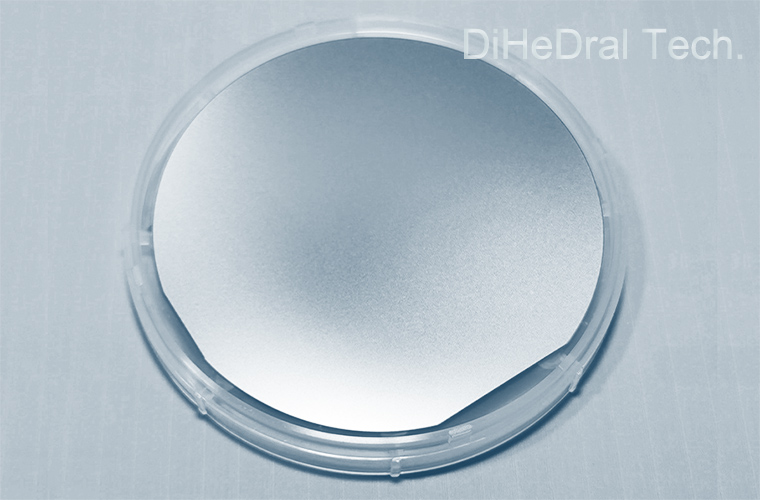

Gallium Oxide epitaxial wafer (Ga2O3)

ε - Gallium Oxide (Ga2O3)

Due to its polarization characteristics, high breakdown electric field, and wide bandgap, ε - Ga ₂ O3 has become an ideal material for high-frequency and high-power electronic devices.

Platinum/Titanium/Silicon Dioxide/Silicon epitacial wafer (Pt/Ti/SiO2/Si)

Lithium niobate thin film epitaxial wafer

Lithium niobate thin film is a thin film made of lithium niobate (LiNbO Å) material, which has many excellent properties, making it widely used in the fields of electronics, optics, and communication.

Lithium tantalate thin film epitaxial wafer

Lithium tantalate thin film is a thin film made of lithium tantalate (LiTaO3) material. LiTaO3 is a crystal material with unique electrical properties, commonly used in the manufacturing of piezoelectric and optical devices.

InGaAs epitaxial wafer

Produce high-performance and high-quality compound semiconductor materials based on gallium arsenide (GaAs), indium phosphide (InP), and indium antimonide (GaSb) substrates.

Gallium Nitride(GaN) epitaxial wafer

GaN epitaxial wafers are a key semiconductor material commonly used for manufacturing high-frequency, high-power, and high-temperature electronic devices, such as high electron mobility transistors (HEMTs) and optoelectronic devices. Gallium nitride has many excellent properties, including high electron mobility, high breakdown electric field strength, excellent thermal stability, and low impurity concentration.

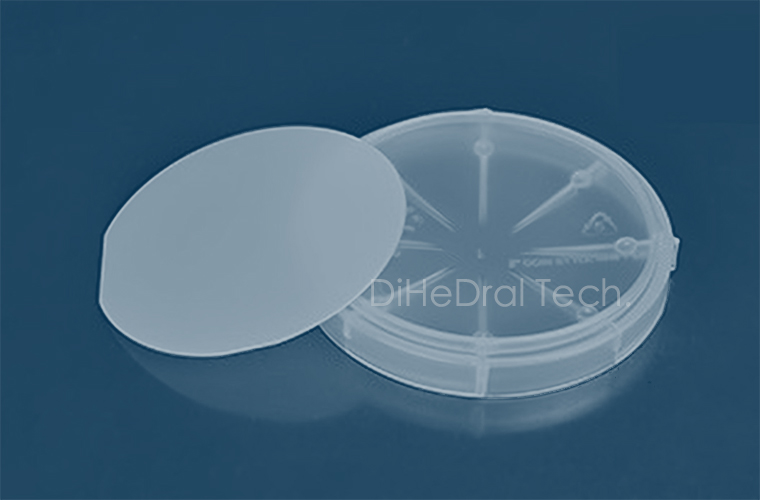

Epitaxial silicon wafer

Silicon epitaxial wafers are commonly used in the field of semiconductor manufacturing, especially in integrated circuit manufacturing. Through epitaxial technology, different silicon layers can be achieved on the same silicon wafer, each with different electrical characteristics. This helps to integrate devices with different functions on the same chip, improving integration and performance.

Yttrium Iron Garnet(YIG) epitaxial wafers

YIG (Yttrium Iron Garnet) belongs to the garnet family. Its chemical formula is Y3Fe5O12, where Y represents yttrium atom, Fe represents iron atom, and O represents oxygen atom. YiG has magnetic and optical properties and is widely used in the fields of optical and microwave devices.

Fullerenes&Fullerols

The molecular structure of C60 is a spherical 32hedron, consisting of 60 carbon atoms connected by 20 hexagonal and 12 pentagonal rings, forming a spherical hollow symmetric molecule with 30 carbon carbon double bonds. Therefore, fullerene is also known as football.

ε-Gallium Oxide(Ga2O3)

Due to its polarization characteristics, high breakdown electric field, and wide bandgap, ε-Ga₂O₃has become an ideal material for high-frequency and high-power electronic devices.

Indium Arsenide (InAs) epitaxial wafer

InAs/GaAs epitaxial wafer refers to a heterostructure material system in which indium arsenide (InAs) quantum dots, quantum wells, or thin films are grown on a gallium arsenide (GaAs) single crystal substrate using molecular beam epitaxy (MBE) or metal organic chemical vapor deposition (MOCVD) techniques.

InGaAs and other compound epitaxial wafers

Produce high-performance and high-quality compound semiconductor materials based on gallium arsenide (GaAs), indium phosphide (InP), and indium antimonide (GaSb) substrates.

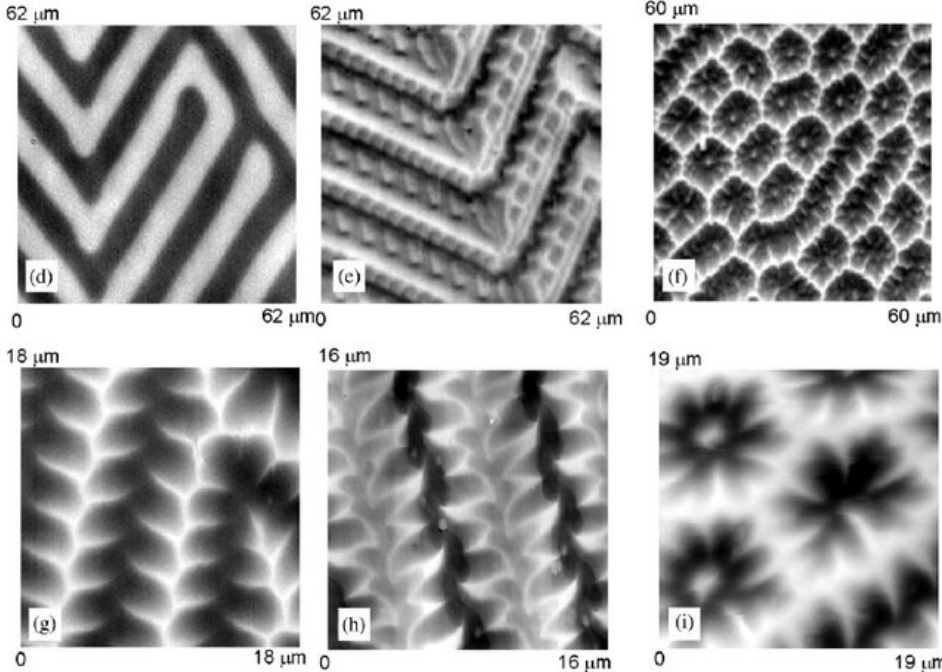

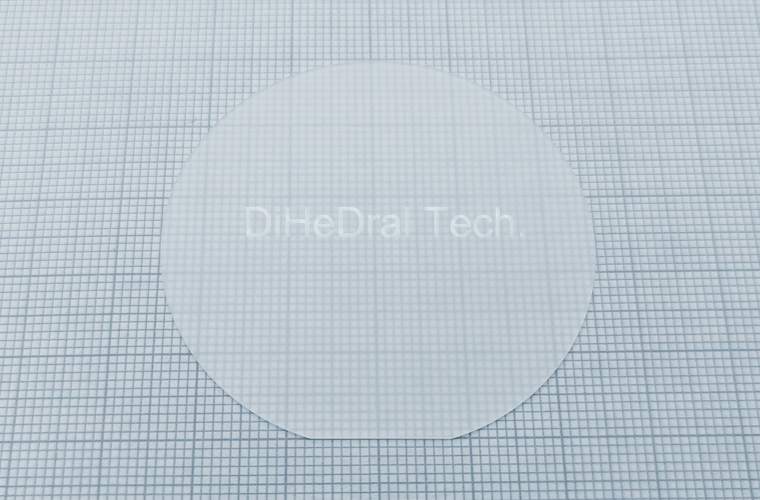

Periodic polarization of lithium niobate PPLN and lithium tantalate PPLT

Periodic polarized lithium niobate and periodic polarized lithium tantalate are ferroelectric crystal materials that achieve quasi phase matching through microdomain engineering.