Dihedral (Shanghai) Science and Technology Co., Ltd

Dihedral (Shanghai) Science and Technology Co., Ltd

- Home

-

Products

-

- Semiconductor crystal

-

Single crystal substrate

-

Multifunctional single crystal substrate

- Barium titanate (BaTiO3)

- Strontium titanate (SrTiO3)

- Iron doped strontium titanate (Fe:SrTiO3)

- Neodymium doped strontium titanate (Nd:SrTiO3)

- Aluminium oxide (Al2O3)

- Potassium tantalum oxide (KTaO3)

- Lead magnesium niobate–lead titanate (PMN-PT)

- Magnesium oxide (MgO)

- Magnesium aluminate spinel (MgAl2O4)

- Lithium aluminate (LiAlO2)

- Lanthanu m aluminate (LaAlO3)

- Lanthanu m strontium aluminate (LaSrAlO4)

- (La,Sr)(Al,Ta)O3

- Neodymium gallate (NdGaO3)

- Terbium gallium garnet (TGG)

- Gadolinium gallium garnet (GGG)

- Sodium chloride (NaCl)

- Potassium bromide (KBr)

- Potassium chloride (KCl)

-

Multifunctional single crystal substrate

-

Functional crystal

- Optical window

- Scintillation crystal

-

Laser crystal

- Rare earth doped lithium yttrium fluoride (RE:LiYF4)

- Rare earth doped lithium lutetium fluoride (RE:LiLuF4)

- Ytterbium doped yttrium aluminium garnet (Yb:YAG)

- Neodymium doped yttrium aluminium garnet (Nd:YAG)

- Erbium doped yttrium aluminium garnet (Er:YAG)

- Holmium doped yttrium aluminium garnet (Ho:YAG)

- Nd,Yb,Er,Tm,Ho,Cr,Lu Infrared laser crystal

- N* crystal

- Metal single crystal

- Material testing analysis

- Material processing

- Scientific research equipment

-

-

Epitaxial Wafer/Films

-

Inorganic epitaxial wafer/film

- Gallium Oxide epitaxial wafer (Ga2O3)

- ε - Gallium Oxide (Ga2O3)

- Platinum/Titanium/Silicon Dioxide/Silicon epitacial wafer (Pt/Ti/SiO2/Si)

- Lithium niobate thin film epitaxial wafer

- Lithium tantalate thin film epitaxial wafer

- InGaAs epitaxial wafer

- Gallium Nitride(GaN) epitaxial wafer

- Epitaxial silicon wafer

- Yttrium Iron Garnet(YIG) epitaxial wafers

- Fullerenes&Fullerols

-

Inorganic epitaxial wafer/film

- Functional Glass

- Fine Ceramics

-

2-D material

- 2-D crystal

-

Layered transition metal compound

- Iron chloride (FeCl2)

- Niobium sulfide (NbS3)

- Gallium telluride iodide (GaTeI)

- Indium selenide (InSe)

- Copper indium phosphide sulfide (CuInP2S6)

- Tungsten sulfide selenide (WSSe)

- Iron germanium telluride (Fe3GeTe2)

- Nickel iodide (NiI2)

- Iron phosphorus sulfide (FePS3)

- Manganese phosphorus selenide (MnPSe3)

- Manganese phosphorus sulfide (MnPS3)

- Interface thermal conductive materials

-

Epitaxial Wafer/Films

-

-

High-purity element

- Non-metallic

-

Metal

- Scandium (Sc)

- Titanium (Ti)

- Indium (In)

- Gallium (Ga)

- Bismuth (Bi)

- Tin (Sn)

- Zinc (Zn)

- Cadmium (Cd)

- Antimony (Sb)

- Copper (Cu)

- Nickel (Ni)

- Molybdenum (Mo)

- Aluminium (Al)

- Rhenium (Re)

- Hafnium (Hf)

- Vanadium (V)

- Chromium (Cr)

- Iron (Fe)

- Cobalt (Co)

- Zirconium (Zr)

- Niobium (Nb)

- Tungsten (W)

- Germanium (Ge)

- Iron(Fe)

-

Compound raw materials

-

Oxide

- Tungsten Trioxide (WO3)

- Hafnium Dioxide (HfO2)

- Ytterbium Oxide (Yb2O3)

- Erbium Oxide (Er2O3)

- Lanthanu m Oxide (La2O3)

- Cerium Dioxide (CeO2)

- Tin Dioxide (SnO2)

- Niobium Oxide (Nb2O3)

- Zirconium Dioxide (ZrO2)

- Zinc Oxide (ZnO)

- Copper Oxide (CuO)

- Magnetite (Fe3O4)

- Titanium Dioxide (TiO2)

- Samarium (III) oxide (Sm2O3)

- Silicon Dioxide (SiO2)

- Aluminum Oxide (Al2O3)

- Gallium Oxide Ga2O3(Powder)

- Sulfide

- Fluoride

- Nitride

- Carbide

-

Halide

- Gallium Chloride (GaCl3)

- Indium Chloride (InCl3)

- Aluminum Chloride (AlCl3)

- Bismuth Chloride (BiCl3)

- Cadmium Chloride (CdCl2)

- Chromium Chloride (CrCl2)

- Chromium Chloride Hydrate (CrCl2(H2O)n)

- Copper Chloride (CuCl)

- Copper Chloride II (CuCl2)

- Cesium Chloride (CsCl)

- Europium Chloride (EuCl3)

- Europium Chloride Hydrate (EuCl3.xH2O)

- Magnesium Chloride (MgCl2)

- Sodium Chloride (NaCl)

- Nickel Chloride (NiCl2)

- Indium Chloride (InCl3)

- Indium Nitrate Hydrate (In(NO3).xH2O)

- Rubidium Chloride (RbCl3)

- Antimony Chloride (SbCl3)

- Samarium Chloride (SmCl3)

- Samarium Chloride Hydrate (SmCl3.xH2O)

- Scandium Chloride (ScCl3)

- Tellurium Chloride (TeCl3)

- Tantalum Chloride (TaCl5)

- Tungsten Chloride (WCl6)

- Aluminum Bromide (AlBr3)

- Barium Bromide (BaBr2)

- Cobalt Bromide (CoBr2)

- Cadmium Bromide (CdBr2)

- Gallium Bromide (GaBr3)

- Gallium Bromide Hydrate (GaBr3.xH2O)

- Nickel Bromide (NiBr2)

- Potassium Bromide (KBr)

- Lead Bromide (PbBr2)

- Zirconium Bromide (ZrBr2)

- Bismuth Bromide (BiBr4)

- Bismuth Iodide (BiI3)

- Calcium Iodide (CaI2)

- Gadolinium Iodide (GdI2)

- Cobalt Iodide (CoI2)

- Cesium Iodide (CsI)

- Europium Iodide (EuI2)

- Lithium Iodide (LiI)

- Lithium Iodide Hydrate (LiI.xH2O)

- Gallium Iodide (GaI3)

- Gadolinium Iodide (GdI3)

- Indium Iodide (InI3)

- Potassium Iodide (KI)

- Lanthanu m Iodide (LaI3)

- Lutetium Iodide (LuI3)

- Magnesium Iodide (MgI2)

- Sodium Iodide (NaI)

-

Oxide

-

High-purity element

-

-

Sputtering Target

-

Metal target material

- Gold (Au(T))

- Silver (Ag(T))

- Platinum (Pt(T))

- Palladium (Pd(T))

- Ruthenium (Ru(T))

- Iridium (Ir(T))

- Aluminium (Al(T))

- Copper (Cu(T))

- Titanium (Ti(T))

- Nickel (Ni(T))

- Chromium (Cr(T))

- Cobalt (Co(T))

- Iron (Fe(T))

- Manganese (Mn(T))

- Zinc (Zn(T))

- Vanadium (V(T))

- Tungsten (W(T))

- Hafnium (Hf(T))

- Niobium (Nb(T))

- Molybdenum (Mo(T))

- Lanthanu m (La (T))

- Cerium (Ce (T))

- Praseodymium (Pr (T))

- Neodymium (Nd (T))

- Samarium (Sm (T))

- Europium (Eu (T))

- Gadolinium (Gd (T))

- Terbium (Tb (T))

- Dysprosium (Dy (T))

- Holmium (Ho (T))

- Erbium (Er (T))

- Thulium (Tm (T))

- Ytterbium (Yb (T))

- Lutetium (Lu (T))

- Alloy target material

- Semiconductor target material

-

Oxide target material

- Aluminum Oxide (Al2O3(T))

- Silicon Dioxide (SiO2(T))

- Titanium Dioxide (TiO2(T))

- Chromium Oxide (Cr2O3(T))

- Nickel Oxide (NiO(T))

- Copper Oxide (CuO(T))

- Zinc Oxide (ZnO(T))

- Zirconium Oxide (ZrO2(T))

- Indium Tin Oxide (ITO(T))

- Indium Zinc Oxide (IZO(T))

- Aluminum Doped Zinc Oxide (AZO(T))

- Cerium Oxide (CeO2(T))

- Tungsten Trioxide (WO3(T))

- Hafnium Oxide (HfO2(T))

- Indium Gallium Zinc Oxide (IGZO(T))

- Nitride target material

- Sulfide target material

-

Antimony tellurium selenium boron target material

- Magnesium Boride (MgB2(T))

- Lanthanu m Hexaboride (LaB6(T))

- Titanium Diboride (TiB2(T))

- Zinc Selenide (ZnSe(T))

- Zinc Antimonide (Zn4Sb3(T))

- Cadmium Selenide (CdSe(T))

- Indium Telluride (In2Te3(T))

- Tin Selenide (SnSe(T))

- Germanium Antimonide (GeSb(T))

- Antimony Selenide (Sb2Se3(T))

- Antimony Telluride (Sb2Te3(T))

- Bismuth Telluride (Bi2Te3(T))

-

Metal target material

-

Sputtering Target

-

- Services

- Media

- Partner

- Contact Us

- About

- Home

- Products

- Semiconductor crystal

- Compound semiconductor

- Silicon carbide (SiC)

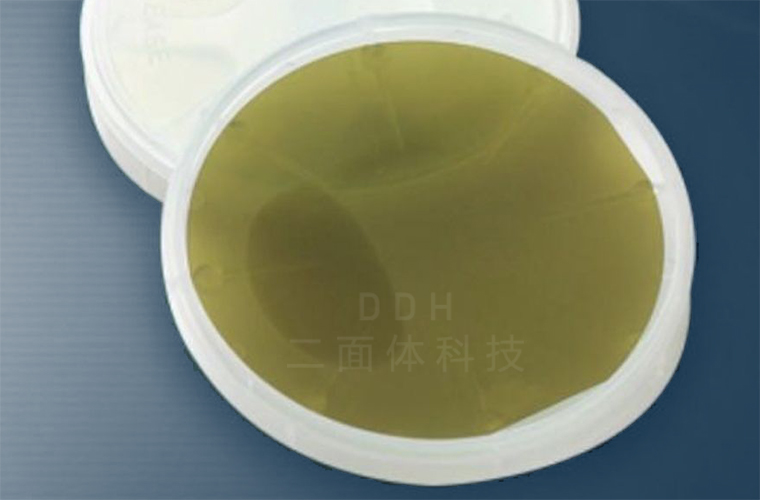

Silicon carbide (SiC)

Silicon carbide (SiC) is a unique semiconductor material with some excellent physical properties. It has attracted widespread attention due to its single crystal structure, unique performance advantages, wide applications, and broad development prospects.

In terms of structure, silicon carbide single crystals mainly have various crystal polymorphisms, including 3C-SiC, 4H-SiC, 6H-SiC, etc. These different crystal structures have their own unique properties. Among them, 4H SiC and 6H SiC are widely used due to their excellent electronic properties and high thermal conductivity.

The performance advantages of silicon carbide mainly include wide band gap, high Electron mobility, strong thermal stability, good chemical stability and excellent thermal conductivity. Among them, the wide bandgap enables SiC to have high electron penetration ability, which is conducive to operating in harsh environments such as high temperature, high pressure, and high frequency. High Electron mobility and thermal conductivity make SiC have good switching performance and heat dissipation performance.

Silicon carbide has a wide range of applications, including power electronics, optoelectronics, high-temperature electronics, automotive electronics, etc. For example, SiC can be used as the basic material for power devices for power conversion and regulation, greatly improving energy efficiency. In the field of optoelectronics, SiC is used to make solar cells due to its ability to withstand extreme environments. In addition, SiC is also widely used in power conversion systems for electric and hybrid vehicles, bringing significant energy efficiency improvements.

The development prospects of silicon carbide are very broad. With the continuous development of technology, the production cost of SiC is gradually decreasing, making it more widely used in various fields. In emerging fields such as new energy vehicles, wind power, and solar power generation, the application of silicon carbide will also be more widely carried out. Meanwhile, with the higher requirements for efficiency in power electronic equipment, the excellent performance of SiC has enormous potential for its application in these fields. Overall, silicon carbide, as an excellent semiconductor material, will have more extensive and in-depth applications in the future.

Dihedral Tech. Co., Ltd. provides high-quality SiC crystal wafers to customers' requirements.

Dihedral Technology(DHD) Co., Ltd. manufacture and processing/provide multiple specifications and high quality SiC crystal,targets,materials.

Applications

• Power electronic equipment: Due to the high temperature and high voltage characteristics of SiC, it is widely used in power electronic equipment, such as power converters, high-frequency switching power supplies, charging equipment, etc.

• Automotive electronics: SiC has a wide range of applications in power electronic converters, on-board chargers and other devices for electric vehicles, which can improve energy efficiency and reduce volume.

• Photovoltaic equipment: SiC materials are used as inverters in photovoltaic equipment, which can improve the conversion efficiency and stability of the system.

• RF equipment: Due to the high-frequency characteristics of SiC, it is widely used in RF power amplifiers and microwave equipment.

• LED lamp: SiC single crystal can be used as a substrate material for blue LED lamp to improve the efficiency and life of LED lamp.

• Thermoelectric devices: SiC's high thermal conductivity and electrical insulation properties make it have great application potential in thermoelectric equipment.

• Wear-resistant materials: Due to the high hardness of SiC, it is often used as a wear-resistant material, such as sandpaper, abrasives, etc.

Features

• High temperature stability: silicon carbide has a very high melting point (about 2730 ° C). It maintains stability in high temperature environments and is suitable for high temperature applications.

• High -hardness: Silicon carbide is a hard material in the world known that it is second only to diamond and cubic boron nitride, so it has important applications on grinding and cutting tools.

• Dagging: In addition to high hardness, silicon carbide also has good abrasion resistance, making it widely used in various applications that need wear resistance.

• Outstanding thermal conductivity: The thermal conductivity of silicon carbide is very high, which makes it advantageous in electronic equipment and other equipment that requires fast dissipation.

• Chemical resistance: Silicon carbide has better corrosion resistance to most chemical reagents, so that it can still maintain performance in various harsh environments.

• Excellent semiconductor characteristics: Silicon carbide energy gap width is large, suitable for power electronic equipment for high voltage and high temperature environments.

• Low -thermal expansion coefficient: The thermal expansion coefficient of silicon carbide is relatively low, making it changes in size when temperature changes, which is conducive to maintaining the stability of the equipment.

• High -intensity: Silicon carbide is a high -intensity material that can work in various high -pressure environments, which is very suitable for high -pressure equipment and components.

-

Growth Method

PVT

Crystal Structure

Hexagonal

Lattice constant

a=3.08 Å c=15.08 Å

Stacking order

ABCACB

Band gap

2.93 eV

Hardness

9.2(mohs)

Thermal conductivity@300K

5 W/ cm.k

Dielectric constant

e(11)=e(22)=9.66 e(33)=10.33

Size

10x3,10x5,10x10,15x15,,20x15,20x20,

Dia2”, 15 x 15 mm,10x10mm

Thickness

0.5mm,1.0mm

Polishing

Single or double sided

Orientation

<001>±0.5º

Orientation accuracy:

±0.5°

Edge orientation accuracy:

2°(up to 1 ° for special requirements)

Ra:

≤5Å(5µm×5µm)

Packing

Class 100 clean bag, Class 1000 ultra clean room