Dihedral (Shanghai) Science and Technology Co., Ltd

Dihedral (Shanghai) Science and Technology Co., Ltd

- Home

-

Products

-

- Semiconductor crystal

-

Single crystal substrate

-

Multifunctional single crystal substrate

- Barium titanate (BaTiO3)

- Strontium titanate (SrTiO3)

- Iron doped strontium titanate (Fe:SrTiO3)

- Neodymium doped strontium titanate (Nd:SrTiO3)

- Aluminium oxide (Al2O3)

- Potassium tantalum oxide (KTaO3)

- Lead magnesium niobate–lead titanate (PMN-PT)

- Magnesium oxide (MgO)

- Magnesium aluminate spinel (MgAl2O4)

- Lithium aluminate (LiAlO2)

- Lanthanu m aluminate (LaAlO3)

- Lanthanu m strontium aluminate (LaSrAlO4)

- (La,Sr)(Al,Ta)O3

- Neodymium gallate (NdGaO3)

- Terbium gallium garnet (TGG)

- Gadolinium gallium garnet (GGG)

- Sodium chloride (NaCl)

- Potassium bromide (KBr)

- Potassium chloride (KCl)

-

Multifunctional single crystal substrate

-

Functional crystal

- Optical window

- Scintillation crystal

-

Laser crystal

- Rare earth doped lithium yttrium fluoride (RE:LiYF4)

- Rare earth doped lithium lutetium fluoride (RE:LiLuF4)

- Ytterbium doped yttrium aluminium garnet (Yb:YAG)

- Neodymium doped yttrium aluminium garnet (Nd:YAG)

- Erbium doped yttrium aluminium garnet (Er:YAG)

- Holmium doped yttrium aluminium garnet (Ho:YAG)

- Nd,Yb,Er,Tm,Ho,Cr,Lu Infrared laser crystal

- N* crystal

- Metal single crystal

- Material testing analysis

- Material processing

- Scientific research equipment

-

-

Epitaxial Wafer/Films

-

Inorganic epitaxial wafer/film

- Gallium Oxide epitaxial wafer (Ga2O3)

- ε - Gallium Oxide (Ga2O3)

- Platinum/Titanium/Silicon Dioxide/Silicon epitacial wafer (Pt/Ti/SiO2/Si)

- Lithium niobate thin film epitaxial wafer

- Lithium tantalate thin film epitaxial wafer

- InGaAs epitaxial wafer

- Gallium Nitride(GaN) epitaxial wafer

- Epitaxial silicon wafer

- Yttrium Iron Garnet(YIG) epitaxial wafers

- Fullerenes&Fullerols

-

Inorganic epitaxial wafer/film

- Functional Glass

- Fine Ceramics

-

2-D material

- 2-D crystal

-

Layered transition metal compound

- Iron chloride (FeCl2)

- Niobium sulfide (NbS3)

- Gallium telluride iodide (GaTeI)

- Indium selenide (InSe)

- Copper indium phosphide sulfide (CuInP2S6)

- Tungsten sulfide selenide (WSSe)

- Iron germanium telluride (Fe3GeTe2)

- Nickel iodide (NiI2)

- Iron phosphorus sulfide (FePS3)

- Manganese phosphorus selenide (MnPSe3)

- Manganese phosphorus sulfide (MnPS3)

- Interface thermal conductive materials

-

Epitaxial Wafer/Films

-

-

High-purity element

- Non-metallic

-

Metal

- Scandium (Sc)

- Titanium (Ti)

- Indium (In)

- Gallium (Ga)

- Bismuth (Bi)

- Tin (Sn)

- Zinc (Zn)

- Cadmium (Cd)

- Antimony (Sb)

- Copper (Cu)

- Nickel (Ni)

- Molybdenum (Mo)

- Aluminium (Al)

- Rhenium (Re)

- Hafnium (Hf)

- Vanadium (V)

- Chromium (Cr)

- Iron (Fe)

- Cobalt (Co)

- Zirconium (Zr)

- Niobium (Nb)

- Tungsten (W)

- Germanium (Ge)

- Iron(Fe)

-

Compound raw materials

-

Oxide

- Tungsten Trioxide (WO3)

- Hafnium Dioxide (HfO2)

- Ytterbium Oxide (Yb2O3)

- Erbium Oxide (Er2O3)

- Lanthanu m Oxide (La2O3)

- Cerium Dioxide (CeO2)

- Tin Dioxide (SnO2)

- Niobium Oxide (Nb2O3)

- Zirconium Dioxide (ZrO2)

- Zinc Oxide (ZnO)

- Copper Oxide (CuO)

- Magnetite (Fe3O4)

- Titanium Dioxide (TiO2)

- Samarium (III) oxide (Sm2O3)

- Silicon Dioxide (SiO2)

- Aluminum Oxide (Al2O3)

- Gallium Oxide Ga2O3(Powder)

- Sulfide

- Fluoride

- Nitride

- Carbide

-

Halide

- Gallium Chloride (GaCl3)

- Indium Chloride (InCl3)

- Aluminum Chloride (AlCl3)

- Bismuth Chloride (BiCl3)

- Cadmium Chloride (CdCl2)

- Chromium Chloride (CrCl2)

- Chromium Chloride Hydrate (CrCl2(H2O)n)

- Copper Chloride (CuCl)

- Copper Chloride II (CuCl2)

- Cesium Chloride (CsCl)

- Europium Chloride (EuCl3)

- Europium Chloride Hydrate (EuCl3.xH2O)

- Magnesium Chloride (MgCl2)

- Sodium Chloride (NaCl)

- Nickel Chloride (NiCl2)

- Indium Chloride (InCl3)

- Indium Nitrate Hydrate (In(NO3).xH2O)

- Rubidium Chloride (RbCl3)

- Antimony Chloride (SbCl3)

- Samarium Chloride (SmCl3)

- Samarium Chloride Hydrate (SmCl3.xH2O)

- Scandium Chloride (ScCl3)

- Tellurium Chloride (TeCl3)

- Tantalum Chloride (TaCl5)

- Tungsten Chloride (WCl6)

- Aluminum Bromide (AlBr3)

- Barium Bromide (BaBr2)

- Cobalt Bromide (CoBr2)

- Cadmium Bromide (CdBr2)

- Gallium Bromide (GaBr3)

- Gallium Bromide Hydrate (GaBr3.xH2O)

- Nickel Bromide (NiBr2)

- Potassium Bromide (KBr)

- Lead Bromide (PbBr2)

- Zirconium Bromide (ZrBr2)

- Bismuth Bromide (BiBr4)

- Bismuth Iodide (BiI3)

- Calcium Iodide (CaI2)

- Gadolinium Iodide (GdI2)

- Cobalt Iodide (CoI2)

- Cesium Iodide (CsI)

- Europium Iodide (EuI2)

- Lithium Iodide (LiI)

- Lithium Iodide Hydrate (LiI.xH2O)

- Gallium Iodide (GaI3)

- Gadolinium Iodide (GdI3)

- Indium Iodide (InI3)

- Potassium Iodide (KI)

- Lanthanu m Iodide (LaI3)

- Lutetium Iodide (LuI3)

- Magnesium Iodide (MgI2)

- Sodium Iodide (NaI)

-

Oxide

-

High-purity element

-

-

Sputtering Target

-

Metal target material

- Gold (Au(T))

- Silver (Ag(T))

- Platinum (Pt(T))

- Palladium (Pd(T))

- Ruthenium (Ru(T))

- Iridium (Ir(T))

- Aluminium (Al(T))

- Copper (Cu(T))

- Titanium (Ti(T))

- Nickel (Ni(T))

- Chromium (Cr(T))

- Cobalt (Co(T))

- Iron (Fe(T))

- Manganese (Mn(T))

- Zinc (Zn(T))

- Vanadium (V(T))

- Tungsten (W(T))

- Hafnium (Hf(T))

- Niobium (Nb(T))

- Molybdenum (Mo(T))

- Lanthanu m (La (T))

- Cerium (Ce (T))

- Praseodymium (Pr (T))

- Neodymium (Nd (T))

- Samarium (Sm (T))

- Europium (Eu (T))

- Gadolinium (Gd (T))

- Terbium (Tb (T))

- Dysprosium (Dy (T))

- Holmium (Ho (T))

- Erbium (Er (T))

- Thulium (Tm (T))

- Ytterbium (Yb (T))

- Lutetium (Lu (T))

- Alloy target material

- Semiconductor target material

-

Oxide target material

- Aluminum Oxide (Al2O3(T))

- Silicon Dioxide (SiO2(T))

- Titanium Dioxide (TiO2(T))

- Chromium Oxide (Cr2O3(T))

- Nickel Oxide (NiO(T))

- Copper Oxide (CuO(T))

- Zinc Oxide (ZnO(T))

- Zirconium Oxide (ZrO2(T))

- Indium Tin Oxide (ITO(T))

- Indium Zinc Oxide (IZO(T))

- Aluminum Doped Zinc Oxide (AZO(T))

- Cerium Oxide (CeO2(T))

- Tungsten Trioxide (WO3(T))

- Hafnium Oxide (HfO2(T))

- Indium Gallium Zinc Oxide (IGZO(T))

- Nitride target material

- Sulfide target material

-

Antimony tellurium selenium boron target material

- Magnesium Boride (MgB2(T))

- Lanthanu m Hexaboride (LaB6(T))

- Titanium Diboride (TiB2(T))

- Zinc Selenide (ZnSe(T))

- Zinc Antimonide (Zn4Sb3(T))

- Cadmium Selenide (CdSe(T))

- Indium Telluride (In2Te3(T))

- Tin Selenide (SnSe(T))

- Germanium Antimonide (GeSb(T))

- Antimony Selenide (Sb2Se3(T))

- Antimony Telluride (Sb2Te3(T))

- Bismuth Telluride (Bi2Te3(T))

-

Metal target material

-

Sputtering Target

-

- Services

- Media

- Partner

- Contact Us

- About

- Home

- Products

- Semiconductor crystal

- Compound semiconductor

- Indium arsenide (InAs)

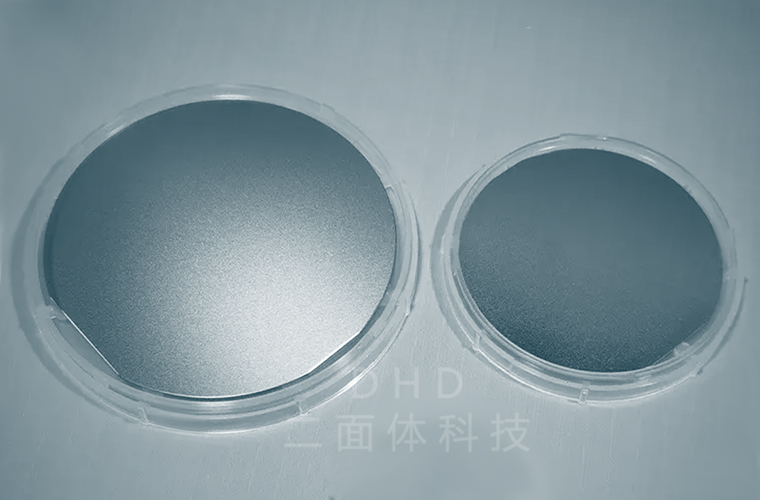

Indium arsenide (InAs)

Indium arsenide (InAs) is a III-V semiconductor material with Sphalerite type single crystal structure. The main advantages of InAs are its high electron mobility and low effective Electron mass, which make InAs have significant advantages in high-speed operation of electronic devices. In addition, InAs also has good photoelectric properties, especially for long wavelength infrared light, with strong absorption and sensitivity.

InAs is widely used in high-speed electronic equipment manufacturing, especially in manufacturing long wave infrared detectors and high electron mobility transistors. This is mainly due to the high electron mobility of InAs, which gives it a significant advantage in the manufacturing of high-speed electronic devices. In addition, due to the strong sensitivity of InAs to long wavelength infrared light, it occupies an important position in the manufacturing of infrared detectors. In addition, InAs is also widely used in the manufacture of optoelectronic devices, such as Photoresistor, photodiodes, etc.

With the development of electronic devices towards higher frequencies and speeds, as well as the advancement of infrared technology, the demand for InAs will continue to grow. However, there are certain technical difficulties in the production process of InAs, and improving production efficiency and reducing costs will be important topics for future research. Overall, InAs is a high-performance semiconductor material with broad application prospects and development potential.

Dihedral Tech. Co., Ltd. provides high-quality InAs crystal wafers to customers' requirements.

Dihedral Technology(DHD) Co., Ltd. manufacture and processing/provide multiple specifications and high quality InAs crystal,targets,materials.

Applications

Infrared detectors: especially for long-wave infrared detectors.

High-speed electronic devices: such as high electron mobility transistors.

Optoelectronic devices: used in the manufacture of various optoelectronic devices.

Features

-Everaging detectors: especially for long wave infrared detectors.

-The high -speed electronic equipment: such as high electronic migration rate transistor.

-The optoelectric components: used to make various optoelectric computers.

-The crystal is grown using liquid sealed Czochralski (LEC) technology, which is mature and has stable electrical properties

-Using an X-ray orientation device for precise orientation, the chip is subjected to chemical mechanical polishing (CMP) to meet the requirements of "ready to use" upon opening the box.

-Special specification product processing can be carried out according to user requirements.

-

Parameters

Single Crystal

Dopant

Conduction Type

Carrier Concentration

(cm-3)

Mobility (cm2/V.s)

Dislocation Density (cm-2)

Standard Substrate

InAs

Undoped

N

5´1016

³2´104

<5´104

Φ2″×0.5mm

Φ3″×0.5mm

InAs

Sn

N

(5-20) ´1017

>2000

<5´104

Φ2″×0.5mm

Φ3″×0.5mm

InAs

Zn

P

(1-20) ´1017

100-300

<5´104

Φ2″×0.5mm

Φ3″×0.5mm

InAs

S

N

(1-10)´1017

>2000

<5´104

Φ2″×0.5mm

Φ3″×0.5mm

Dimension

Dia50.8x0.5mm,10×10×0.5mm、10×5×0.5mm

According to customer needs, substrates with special orientations and sizes can be customized.

Surface Roughness

Surface roughness(Ra):<=5 Å

Atomic particle microscope ( AFM ) test report can be providedPolishing

One side or two sides

Package

Class 100 clean bag, Class 1000 super clean room