Dihedral (Shanghai) Science and Technology Co., Ltd

Dihedral (Shanghai) Science and Technology Co., Ltd

- Home

-

Products

-

- Semiconductor crystal

-

Single crystal substrate

-

Multifunctional single crystal substrate

- Barium titanate (BaTiO3)

- Strontium titanate (SrTiO3)

- Iron doped strontium titanate (Fe:SrTiO3)

- Neodymium doped strontium titanate (Nd:SrTiO3)

- Aluminium oxide (Al2O3)

- Potassium tantalum oxide (KTaO3)

- Lead magnesium niobate–lead titanate (PMN-PT)

- Magnesium oxide (MgO)

- Magnesium aluminate spinel (MgAl2O4)

- Lithium aluminate (LiAlO2)

- Lanthanu m aluminate (LaAlO3)

- Lanthanu m strontium aluminate (LaSrAlO4)

- (La,Sr)(Al,Ta)O3

- Neodymium gallate (NdGaO3)

- Terbium gallium garnet (TGG)

- Gadolinium gallium garnet (GGG)

- Sodium chloride (NaCl)

- Potassium bromide (KBr)

- Potassium chloride (KCl)

-

Multifunctional single crystal substrate

-

Functional crystal

- Optical window

- Scintillation crystal

-

Laser crystal

- Rare earth doped lithium yttrium fluoride (RE:LiYF4)

- Rare earth doped lithium lutetium fluoride (RE:LiLuF4)

- Ytterbium doped yttrium aluminium garnet (Yb:YAG)

- Neodymium doped yttrium aluminium garnet (Nd:YAG)

- Erbium doped yttrium aluminium garnet (Er:YAG)

- Holmium doped yttrium aluminium garnet (Ho:YAG)

- Nd,Yb,Er,Tm,Ho,Cr,Lu Infrared laser crystal

- N* crystal

- Metal single crystal

- Material testing analysis

- Material processing

- Scientific research equipment

-

-

Epitaxial Wafer/Films

-

Inorganic epitaxial wafer/film

- Gallium Oxide epitaxial wafer (Ga2O3)

- ε - Gallium Oxide (Ga2O3)

- Platinum/Titanium/Silicon Dioxide/Silicon epitacial wafer (Pt/Ti/SiO2/Si)

- Lithium niobate thin film epitaxial wafer

- Lithium tantalate thin film epitaxial wafer

- InGaAs epitaxial wafer

- Gallium Nitride(GaN) epitaxial wafer

- Epitaxial silicon wafer

- Yttrium Iron Garnet(YIG) epitaxial wafers

- Fullerenes&Fullerols

- ε-Gallium Oxide(Ga2O3)

- Indium Arsenide (InAs) epitaxial wafer

- InGaAs and other compound epitaxial wafers

- Periodic polarization of lithium niobate PPLN and lithium tantalate PPLT

-

Inorganic epitaxial wafer/film

- Functional Glass

- Fine Ceramics

-

2-D material

- 2-D crystal

-

Layered transition metal compound

- Iron chloride (FeCl2)

- Niobium sulfide (NbS3)

- Gallium telluride iodide (GaTeI)

- Indium selenide (InSe)

- Copper indium phosphide sulfide (CuInP2S6)

- Tungsten sulfide selenide (WSSe)

- Iron germanium telluride (Fe3GeTe2)

- Nickel iodide (NiI2)

- Iron phosphorus sulfide (FePS3)

- Manganese phosphorus selenide (MnPSe3)

- Manganese phosphorus sulfide (MnPS3)

- Interface thermal conductive materials

-

Epitaxial Wafer/Films

-

-

High-purity element

- Non-metallic

-

Metal

- Scandium (Sc)

- Titanium (Ti)

- Indium (In)

- Gallium (Ga)

- Bismuth (Bi)

- Tin (Sn)

- Zinc (Zn)

- Cadmium (Cd)

- Antimony (Sb)

- Copper (Cu)

- Nickel (Ni)

- Molybdenum (Mo)

- Aluminium (Al)

- Rhenium (Re)

- Hafnium (Hf)

- Vanadium (V)

- Chromium (Cr)

- Iron (Fe)

- Cobalt (Co)

- Zirconium (Zr)

- Niobium (Nb)

- Tungsten (W)

- Germanium (Ge)

- Iron(Fe)

-

Compound raw materials

-

Oxide

- Tungsten Trioxide (WO3)

- Hafnium Dioxide (HfO2)

- Ytterbium Oxide (Yb2O3)

- Erbium Oxide (Er2O3)

- Lanthanu m Oxide (La2O3)

- Cerium Dioxide (CeO2)

- Tin Dioxide (SnO2)

- Niobium Oxide (Nb2O3)

- Zirconium Dioxide (ZrO2)

- Zinc Oxide (ZnO)

- Copper Oxide (CuO)

- Magnetite (Fe3O4)

- Titanium Dioxide (TiO2)

- Samarium (III) oxide (Sm2O3)

- Silicon Dioxide (SiO2)

- Aluminum Oxide (Al2O3)

- Gallium Oxide Ga2O3(Powder)

- Sulfide

- Fluoride

- Nitride

- Carbide

-

Halide

- Gallium Chloride (GaCl3)

- Indium Chloride (InCl3)

- Aluminum Chloride (AlCl3)

- Bismuth Chloride (BiCl3)

- Cadmium Chloride (CdCl2)

- Chromium Chloride (CrCl2)

- Chromium Chloride Hydrate (CrCl2(H2O)n)

- Copper Chloride (CuCl)

- Copper Chloride II (CuCl2)

- Cesium Chloride (CsCl)

- Europium Chloride (EuCl3)

- Europium Chloride Hydrate (EuCl3.xH2O)

- Magnesium Chloride (MgCl2)

- Sodium Chloride (NaCl)

- Nickel Chloride (NiCl2)

- Indium Chloride (InCl3)

- Indium Nitrate Hydrate (In(NO3).xH2O)

- Rubidium Chloride (RbCl3)

- Antimony Chloride (SbCl3)

- Samarium Chloride (SmCl3)

- Samarium Chloride Hydrate (SmCl3.xH2O)

- Scandium Chloride (ScCl3)

- Tellurium Chloride (TeCl3)

- Tantalum Chloride (TaCl5)

- Tungsten Chloride (WCl6)

- Aluminum Bromide (AlBr3)

- Barium Bromide (BaBr2)

- Cobalt Bromide (CoBr2)

- Cadmium Bromide (CdBr2)

- Gallium Bromide (GaBr3)

- Gallium Bromide Hydrate (GaBr3.xH2O)

- Nickel Bromide (NiBr2)

- Potassium Bromide (KBr)

- Lead Bromide (PbBr2)

- Zirconium Bromide (ZrBr2)

- Bismuth Bromide (BiBr4)

- Bismuth Iodide (BiI3)

- Calcium Iodide (CaI2)

- Gadolinium Iodide (GdI2)

- Cobalt Iodide (CoI2)

- Cesium Iodide (CsI)

- Europium Iodide (EuI2)

- Lithium Iodide (LiI)

- Lithium Iodide Hydrate (LiI.xH2O)

- Gallium Iodide (GaI3)

- Gadolinium Iodide (GdI3)

- Indium Iodide (InI3)

- Potassium Iodide (KI)

- Lanthanu m Iodide (LaI3)

- Lutetium Iodide (LuI3)

- Magnesium Iodide (MgI2)

- Sodium Iodide (NaI)

-

Oxide

-

High-purity element

-

-

Sputtering Target

-

Metal target material

- Gold (Au(T))

- Silver (Ag(T))

- Platinum (Pt(T))

- Palladium (Pd(T))

- Ruthenium (Ru(T))

- Iridium (Ir(T))

- Aluminium (Al(T))

- Copper (Cu(T))

- Titanium (Ti(T))

- Nickel (Ni(T))

- Chromium (Cr(T))

- Cobalt (Co(T))

- Iron (Fe(T))

- Manganese (Mn(T))

- Zinc (Zn(T))

- Vanadium (V(T))

- Tungsten (W(T))

- Hafnium (Hf(T))

- Niobium (Nb(T))

- Molybdenum (Mo(T))

- Lanthanu m (La (T))

- Cerium (Ce (T))

- Praseodymium (Pr (T))

- Neodymium (Nd (T))

- Samarium (Sm (T))

- Europium (Eu (T))

- Gadolinium (Gd (T))

- Terbium (Tb (T))

- Dysprosium (Dy (T))

- Holmium (Ho (T))

- Erbium (Er (T))

- Thulium (Tm (T))

- Ytterbium (Yb (T))

- Lutetium (Lu (T))

- Alloy target material

- Semiconductor target material

-

Oxide target material

- Aluminum Oxide (Al2O3(T))

- Silicon Dioxide (SiO2(T))

- Titanium Dioxide (TiO2(T))

- Chromium Oxide (Cr2O3(T))

- Nickel Oxide (NiO(T))

- Copper Oxide (CuO(T))

- Zinc Oxide (ZnO(T))

- Zirconium Oxide (ZrO2(T))

- Indium Tin Oxide (ITO(T))

- Indium Zinc Oxide (IZO(T))

- Aluminum Doped Zinc Oxide (AZO(T))

- Cerium Oxide (CeO2(T))

- Tungsten Trioxide (WO3(T))

- Hafnium Oxide (HfO2(T))

- Indium Gallium Zinc Oxide (IGZO(T))

- Nitride target material

- Sulfide target material

-

Antimony tellurium selenium boron target material

- Magnesium Boride (MgB2(T))

- Lanthanu m Hexaboride (LaB6(T))

- Titanium Diboride (TiB2(T))

- Zinc Selenide (ZnSe(T))

- Zinc Antimonide (Zn4Sb3(T))

- Cadmium Selenide (CdSe(T))

- Indium Telluride (In2Te3(T))

- Tin Selenide (SnSe(T))

- Germanium Antimonide (GeSb(T))

- Antimony Selenide (Sb2Se3(T))

- Antimony Telluride (Sb2Te3(T))

- Bismuth Telluride (Bi2Te3(T))

-

Metal target material

-

Sputtering Target

-

- Services

- Media

- Partner

- Contact Us

- About

- Home

- Products

- High-purity element

- Metal

- Iron(Fe)

Iron(Fe)

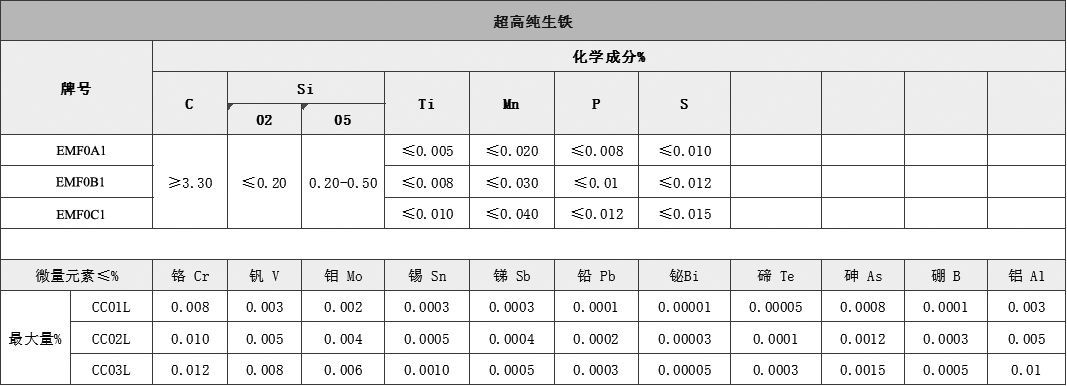

Pig iron is a primary product obtained when extracting iron ore from blast furnaces. It has a high carbon content, usually between 2% and 4%, and also contains impurities such as silicon, manganese, phosphorus, and sulfur.

Pig iron has high hardness and brittleness, making it unsuitable for forging, but it can be used for casting. Mainly used as raw materials for manufacturing steel or cast iron.

The main characteristics are as follows:

1. Low melting point: Compared to pure iron, pig iron contains a higher carbon content (usually between 2% and 4%), which lowers its melting point and makes it easier to melt and recast.

2. Easy to cast: Pig iron has good fluidity, which allows it to be easily cast into complex shapes. This characteristic makes pig iron an ideal choice for manufacturing mechanical parts and other industrial products.

3. Low cost: The production cost of pig iron is relatively low, especially in large-scale production. Pig iron is directly refined from iron ore without the need for complex processing procedures.

4. Good hardness and wear resistance: Although pig iron is brittle, its hardness and wear resistance make it suitable for manufacturing parts that require hardness but do not withstand impact loads, such as bases, frames, and certain types of tools.

5. Can be reprocessed into other types of iron: Pig iron is the main raw material for manufacturing cast iron and steel. By adjusting the carbon content and adding other alloying elements, pig iron can be transformed into various types of cast iron or steel for a wider range of applications.

6. For the production of alloys: Carbon and other elements such as silicon, manganese, phosphorus, and sulfur in pig iron make it the basis for manufacturing various iron-based alloys.

Dihedral (Shanghai) Technology Co., Ltd. provides high-purity and ultra high purity pig iron.

Applications

Mainly used as raw materials for manufacturing steel or cast iron.

Features

1. Low melting point.

2. Easy to cast.

3. Low cost.

4. Good hardness and wear resistance.

5. It can be further processed into other types of iron.

6. Used for the production of alloys.